Pharma Packaging

Pharma Packaging.

OEM SOLUTION FOR THE AUTOMATIC SEAL INTEGRITY INSPECTION  OF MEDICAL DEVICE PACKAGES.

OF MEDICAL DEVICE PACKAGES.

KEY CHALLENGE IN PHARMACEUTICAL PACKAGES: 100 % SEAL INTEGRITY.

Total seal integrity of delivered pharmaceutical packages is of crucial importance because harmful contaminants may enter a package through seal defects.

Existing standardized test methods such as dye penetration and bubble tests are destructive to the packaging. Traditional machine vision systems are unable to detect seal imperfections in any reliable way.

The goal is to find a non-destructive and reliable test method that allows for the automatic on-line testing of all the packages produced.

AUTOMATIC NON-DESTRUCTIVE ON-LINE SOLUTION BY LCI TECHNOLOGY

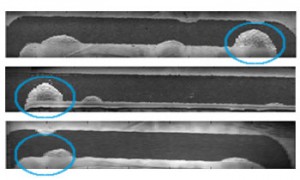

Line Confocal Imaging technology (LCI) has the unique ability to accurately measure the distance to each material surface in a transparent target: A flawless heat seal is detected as one surface, but an air gap in the seal layer causes the seal to be detected as two surfaces.

Both 2D and 3D images of all the surface layers and possible seal defects are recorded simultaneously by just one LCI scan with a micrometer Z resolution. The signal processing needed to generate this 2D and 3D image information is taken care by in-built signal processing power in FocalSpec LCI measurement heads, which greatly reduces burden on other system components and makes the integration work significantly faster and simpler.

The 2D and 3D seal layer images can then be easily processed by a standard computer system allowing for the fast, reliable and automated detection of seal defects invisible to naked eye and traditional machine vision systems.

Detected defect types include: incomplete seals, inclusions, wrinkles, channel defects, misaligned seal, delaminations, pinholes, particles in seal area.

LCI allows for a reliable and non-destructive test method for heat seals. A flawless heat seal is detected as one surface, but a <1 μm air gap in the seal layer causes the seal to be detected as two surfaces