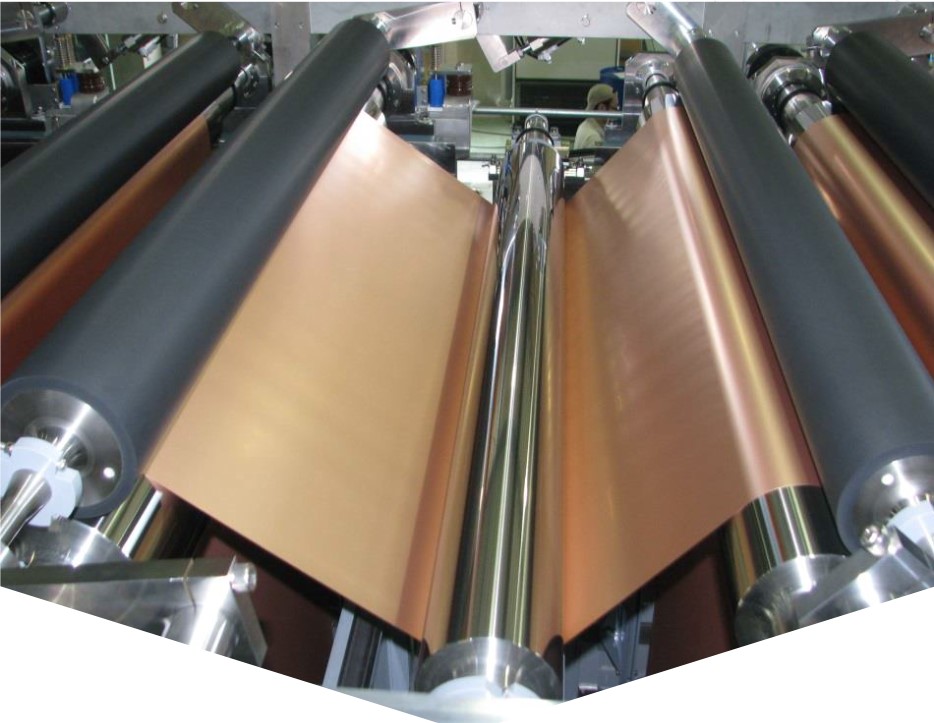

Metal & Copper foil

- Home

- Industry

- Metal & Copper foil

Metal & Copper foil

Application

Generally, WebPage system is installed in the non-continuous production lines, which is used to inspect the defects on the appearance of non-continuous board materials (such as paper board and metal substrate) and sheet materials (such as glass, ceramics, optics and electronic substrate).

The metal industries such as stainless steel strip, copper foil and aluminum foil, and electronic industries such as ITO glass, liquid crystal glass, ceramic substrate and Copper Clad Laminate (CCL) are mostly products with high value added. Higher yield rate and capacity will bring significant economic benefits. AOI equipment could inspect the minor defects that can’t be discovered visually, increase the inspection speed, perform real-time monitoring, and feedback data and information.

Inspection specifications

- Inspection methods: Online/offline

- Product width, thickness and color: Samples are provided for testing as required, which are subject to the test results and evaluation schemes.

- Defect inspection accuracy: It is subject to the requirements, and the value higher than 0.01mm is recommended in general cases.

- Camera: High-resolution camera with fine-tuning mechanism and industrial precision optical lens

- Central control system: The integrated cabinet contains data processing, IO control, voltage stabilization and cooling systems

- Light source system: High LM and LUX LED linear light source unit

- Clean transmission system: Optional

Software functions

- Advanced image processing technology allows user to modify, setup, store and upload the system parameters.

- When a defect is inspected, the system will light up alarm indicators or make alarm sounds. At the meantime, the defect will be shown on the screen, so the personnel will identify it immediately. Moreover, the defect data and images will be stored in the database.

- The system could output various real-time or delayed signals to start up the labeling machine, ink-jet machine or other hardware.

- I/O control supports customized design based on different requirem

- NG or Pass categories could be classified, or class A/B/C/D can be divided.

- Various reports and statistical analysis charts built in the system could be printed as required, or customized reports can be generated based on different requirements.

- It can be connected with mobile devices or managed remotely.

Defect images