300 MHz NMR Spectroscopy Magnet

- Home

- Scientific

- HTS Current Leads

- 300 MHz NMR Spectroscopy Magnet

300 MHz NMR Spectroscopy Magnet

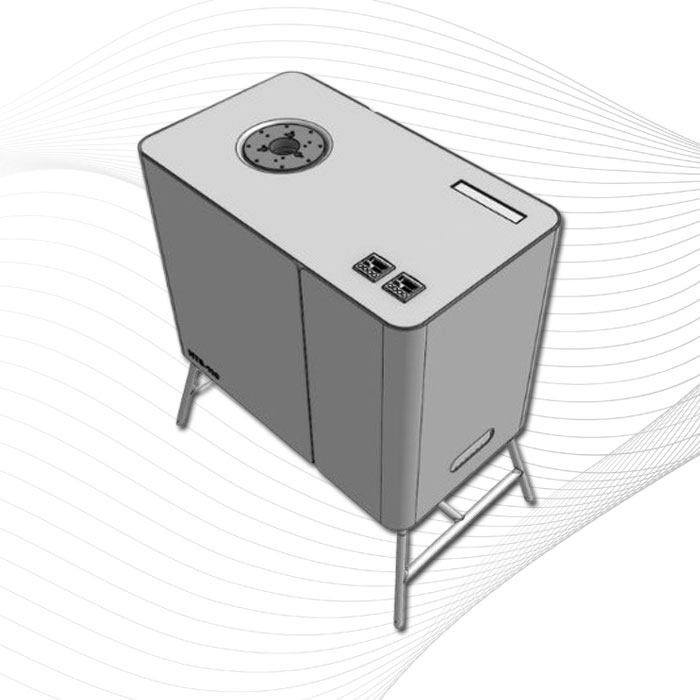

Building on our legacy of high-resolution dry NMR, HTS‐110 proudly introduces an all-new 300 MHz magnet that’s helium‐free, energy‐efficient, and purposefully designed to be more compact than ever before.

TURNKEY SPECTROMETER SYSTEM IN DEVELOPMENT

- HTS MAGNET AVAILABLE

- Enquire today for a bespoke HTS system

Features

Experience high-resolution NMR without the complexity of liquid helium. HTS-110’s 300 MHz magnet platform harnesses 2nd-generation HTS coils to deliver ~7 T of field strength at temperatures around 50 K—all while drawing under 1.2 kW from a single-phase outlet. The compact bore and integrated cryocooler design drastically reduce lab overhead, making advanced spectroscopy feasible for a broader range of research, industrial QA, and educational settings.

Builds Upon Proven 400 MHz Results

Refined design principles and in-house know-how from our successful high-resolution, cryogen-free 400 MHz magnet. This is a pre-release model. We welcome your feedback to help shape the final production system. We are accepting technical enquiries for bespoke projects and from instrumentation or integration partners.

- Chemical & Pharmaceutical Research. Reaction monitoring, structure elucidation, and process control in industrial or academic labs.

- Educational Institutions. A robust teaching tool for undergrad and graduate chemistry programs—no helium handling needed.

- Mobile & Remote Testing. Potential for deployment on a movable cart or in remote labs, thanks to vibration‐tolerant construction and simpler site requirements.

- Energy & Advanced Materials. Suitable for investigating novel materials, battery chemistry, and next‐gen fusion or fission projects where portability matters.

Easy to site

- Cryocooler uses <1.2 kW from a normal wall outlet—no 3‑phase supply required.

Helium-Free Operation

- Eliminates liquid helium shipments, transfers, and boil-off concerns.

Compact Bore

- Increased efficiency, suitable for standard 5 mm tubes while minimising overall footprint.

Sealed Cryocooler

- Minimal servicing, no cryogen training needed.

Preliminary Footprint

- ~774 x 456 mm, ~180 kg total mass.

Model Specifications

- System Components

- Magnet Sub‐System : Fully integrated HTS magnet, self-shielded with an iron yoke and vacuum jacket, plus the miniature cryocooler assembly

- Power Supply : High‐stability power supply designed for ramping, field maintenance, and integrated with quench protection

- Monitoring Electronics : Monitor real‐time coil temperatures and voltages; active protection circuitry is built in to safeguard the magnet

- Warranty : 1‐year standard warranty on all magnet sub‐systems

Site and Operating Environment

- Helium‐Free : no deliveries, dewars, transfers, or venting required

- Power : single-phase AC <1.2 kW (suitable for standard outlets or a UPS)

- Cooling : onboard sealed cryocooler with minimal servicing—no cryogen training required

- Optional water chiller for the cryocooler if no facility water line is available

- Installation : sits on the floor or can be adapted for caster-based mobility, no special vibration isolation needed

- Safety : low fringe field due to integrated iron yoke; final anchoring method or seismic considerations may apply