Surface Roughness Measurement

ONLINE SURFACE ROUGHNESS MEASUREMENT

for improved product quality and increased production output

This application note discusses how surface roughness of an extrudate depends on extrusion processing conditions. Results from experimental test runs with varying barrel temperature, screw speed and pull tension are presented. A new in-line roughness measurement technology is introduced and its use in the production of polymer tubing is explored. This paper also discusses how real-time roughness monitoring can be used as an efficient tool in optimizing tube extrusion processes resulting in improved quality and increased production volume.

Introduction

A recent study conducted at Tampere University of Technology in Finland focused on finding out the relation between key extrusion process parameters and surface roughness of the extrudate. Two polymer materials were extruded without and with color masterbatch in varying process conditions at different barrel temperature, extruder screw speed and pull tension, and the surface roughness level of the extrudate was observed and measured in each case.

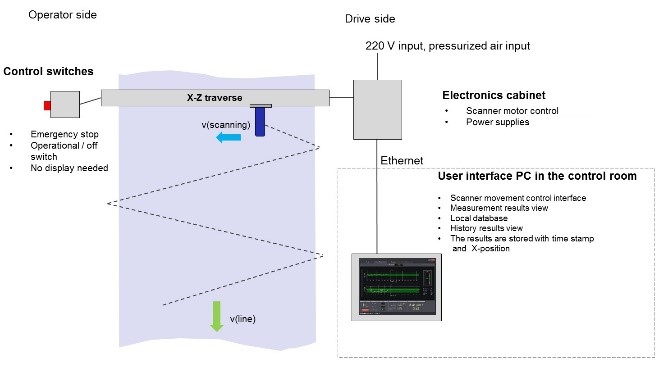

In this study surface roughness was measured from film produced on the university’s laboratory cast film line. We believe that the results from this study can be extrapolated to tube extrusion processes as well. All the roughness readings were taken with a new inline optical roughness measurement system that enables continuous monitoring of surface roughness during the extrusion process, including parameter change periods. Without the real-time roughness data acquisition capabilities provided by the system a study like this would have been virtually impossible to conduct.