Optical film

- Home

- Industry

- Optical film

Optical film

Application

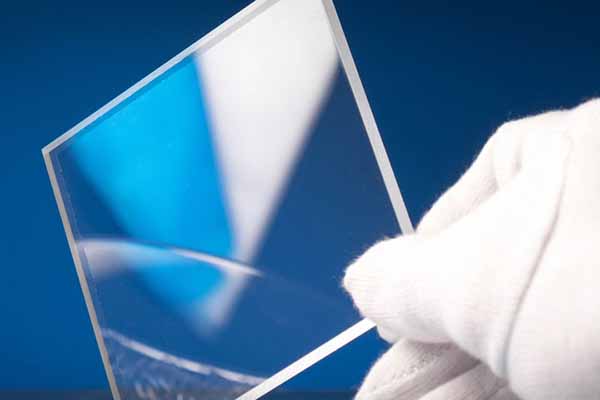

The continuous surface defect inspection system (WebScan) is widely applied in the online and offline inspection of plastic film, optical film, and composite film, including:

- Plastic film and sheet in the plastics industry such as PP, PVC, PE, PET, and BOPP

- Optoelectronic materials such as light guide plate, diffusion film, brightness enhancement film and protective film.

- Synthetic operation of composite materials such as lamination and precision coating, such as glass fiber impregnated resin sheet

The inspection equipment can be installed in different machines during the production such as the film blowing machine, film molding machine, coating machine, slitting machine and roller.

Inspection specifications

- Product width, thickness and color: Samples are provided for testing as required, which are subject to the test results and evaluation schemes.

- Processing speed: High-precision cameras are provided based on the requirements of processing speed and defect inspection accuracy.

- Defect inspection accuracy: It is subject to the requirements, which can reach 0.01mm.

- Camera: High-resolution camera with fine-tuning mechanism and industrial precision optical lens

- Central control system: The integrated cabinet contains data processing, IO control, voltage stabilization and cooling systems

- Light source system: High LM and LUX LED linear light source unit

Software functions

- Real-time defect information

- Defect map (Front/rear sides)

- Inquiry of defect history

- Defect statistics, analysis and run chart

- Customization of various reports

- Defect alarms including alarm indicator, labeling, ink-jet, underlining, and shutdown

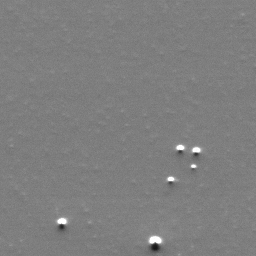

Defect images